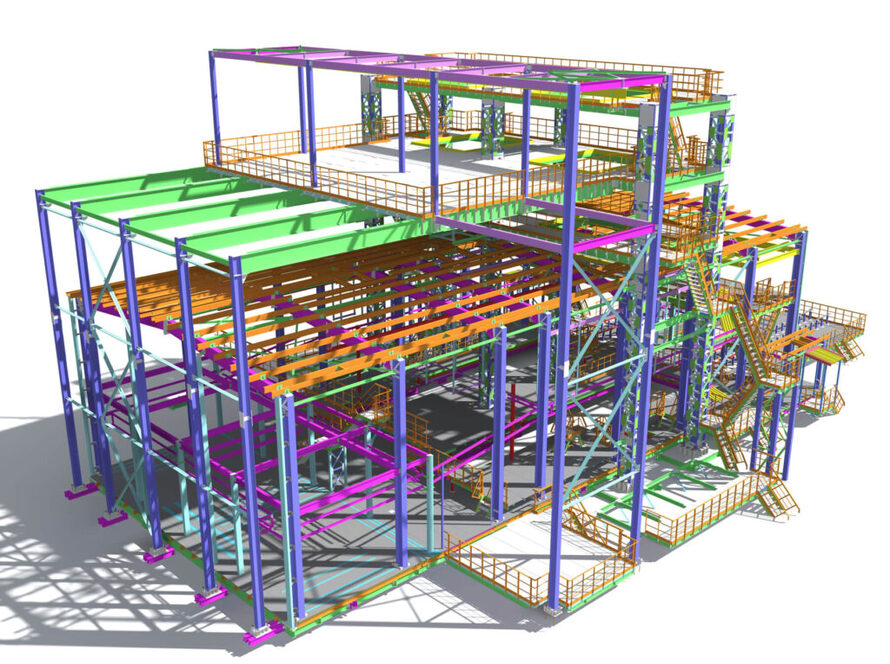

At BD Steel Detailing Services, our commitment to excellence in Structural and Miscellaneous Steel Detailing sets us apart as industry leaders. Our highly skilled team of steel detailers employs state-of-the-art software tools to meticulously craft detailed 3D models and drawings.We pride ourselves on the precision of our detailing process, ensuring that every element, from connection details to material specifications, adheres to the highest standards of accuracy. Involves creating detailed drawings and models for the fabrication and erection of structural steel components, such as beams, columns, and braces. This process ensures that all steel elements fit together seamlessly and meet design specifications. At SteelInnovate, we are not just detailers; we are partners in innovation, guiding projects to successful fruition through precision, quality, and a commitment to exceeding client expectations.

Working collaboratively, the BD Steel Detailing Services team has aided in design and detailing assistance for structures such as One World Trade Center and the Hearst Tower. Together with clients and partners, this service speeds up project timelines and can help save on costs. For us, one of the most important aspects of steel detailing is the partnership with owners, architects and other engineers. For example, an owner rethinking the use of certain spaces throughout a building may call on us to address any new engineering concerns by utilizing our model. Or, if changes are made after erection has started, we can address the issues of having them incorporated onto the detail drawings and work with the fabricator and erector to minimize cost and time impacts. With structural detailing, collaboration is a key to success.